Assam-With the rapid development of science and technology, my country’s manufacturing industry is gradually moving towards intelligence and automation. In the field of metal parts processing, the advent of intelligent robot metal parts magnetic tumbling polishing machine provides a strong guarantee for improving production efficiency, reducing labor intensity and improving product quality. This article will discuss the principle, characteristics and application of intelligent robot metal parts magnetic tumbling polishing machine in the manufacturing industry.

1. Principle of intelligent robot metal parts magnetic tumbling polishing machine

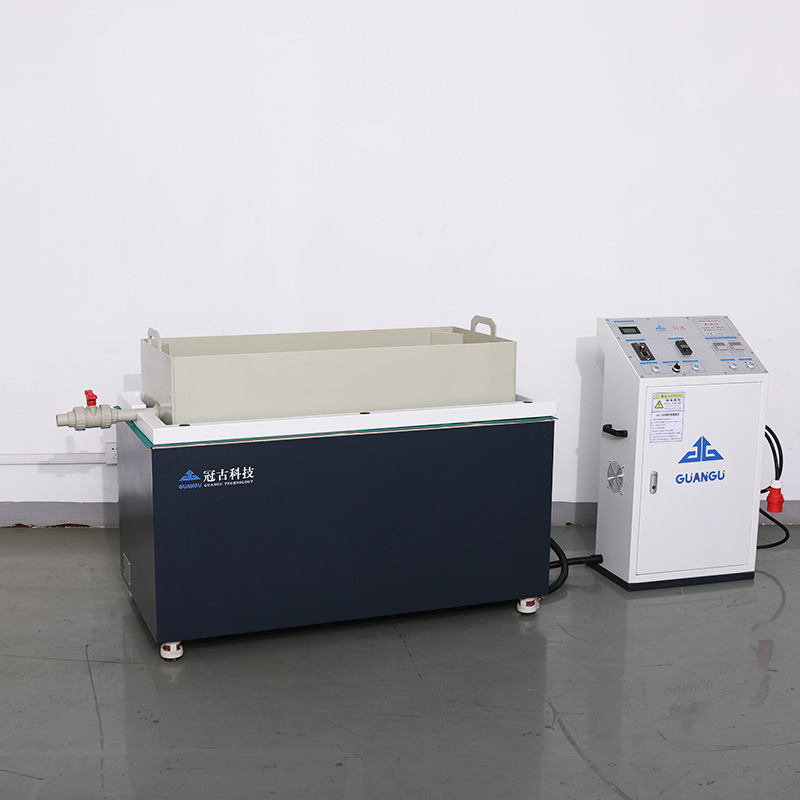

Intelligent robot metal parts magnetic tumbling polishing machine is an advanced equipment integrating robot technology, magnetic field control technology and polishing technology. Its working principle is as follows:

Robot grabbing: Through programming control, the intelligent robot accurately grabs metal parts.

Magnetic field control: Use the magnetic field generated by the electromagnet to adsorb and fix the metal parts.

Polishing operation: Under the action of the magnetic field, the metal parts tumble in the polishing medium to achieve efficient and uniform polishing effect.

2. Features of Intelligent Robot Metal Parts Magnetic Tumbling Polishing Machine

High efficiency: Compared with traditional polishing equipment, the intelligent robot metal parts magnetic tumbling polishing machine has higher polishing efficiency and greatly shortens the production cycle.

High degree of automation: Through programming control, the whole process of automated operation is realized, which reduces the skill requirements for operators.

Good polishing effect: The magnetic tumbling polishing technology is adopted to make the surface finish of metal parts higher and more consistent.

Energy saving and environmental protection: During the operation of the equipment, the energy consumption is low and the noise is low, which conforms to the concept of green manufacturing.

Strong adaptability: It is suitable for polishing metal parts of various shapes, sizes and materials.

3. Application of intelligent robot metal parts magnetic tumbling polishing machine in manufacturing industry

Automotive parts: In the automotive industry, many metal parts need to be polished, such as engine cylinder blocks, cylinder heads, gearbox gears, etc. The use of intelligent robot metal parts magnetic tumbling polishing machine can improve the surface quality of parts and extend their service life.

Mechanical manufacturing: Metal parts such as gears, bearings, fasteners, etc. in the machinery industry can achieve higher precision and better wear resistance through magnetic tumbling polishing.

Hardware products: Hardware products such as locks, bathroom accessories, etc., after magnetic tumbling polishing, the surface finish is improved and more competitive in the market.

3C electronics: The metal parts in 3C products such as mobile phones and computers are polished by intelligent robot magnetic tumbling polishing machines, which helps to improve the appearance and performance of the products.

In short, the intelligent robot metal parts magnetic tumbling polishing machine provides strong technical support for my country’s manufacturing industry, helps to promote industrial upgrading and improve the international competitiveness of my country’s manufacturing industry. With the continuous advancement of technology, I believe this equipment will play an important role in more fields.

Wechat

Wechat